Contact Us

Longgang District, Shenzhen City,china

16

2024-07

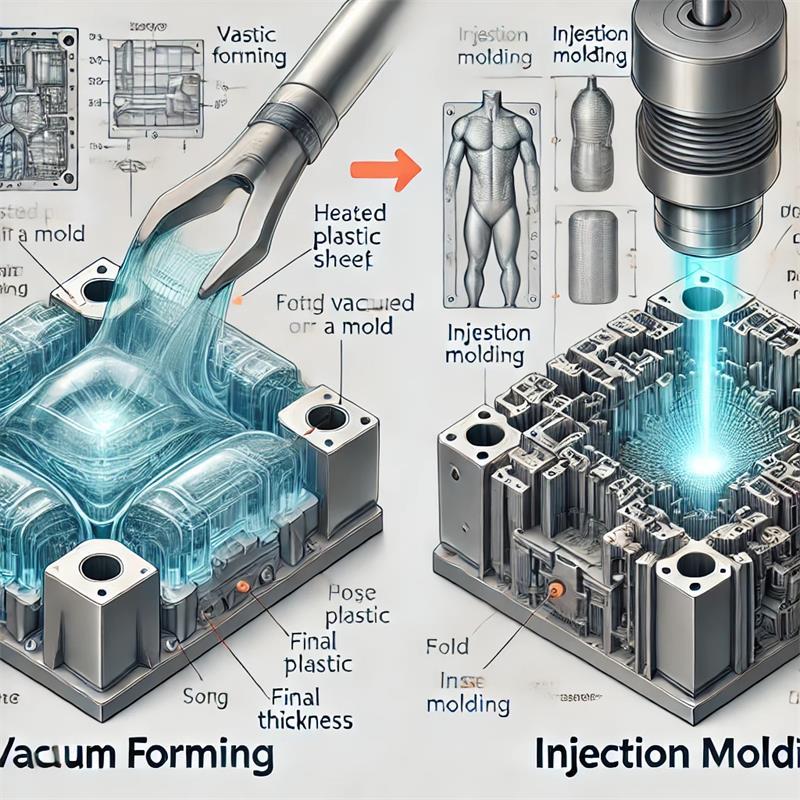

The choice between injection molding and thermoforming can significantly impact the efficiency, cost, and quality of a product. While injection molding is highly effective for certain applications, thermoforming offers distinct advantages, particularly for larger parts and lower production volumes. Here's a guide on how to transition from injection molding to thermoforming, the benefits of doing so, and how our professional design solutions can support this shift.

28

2022-07

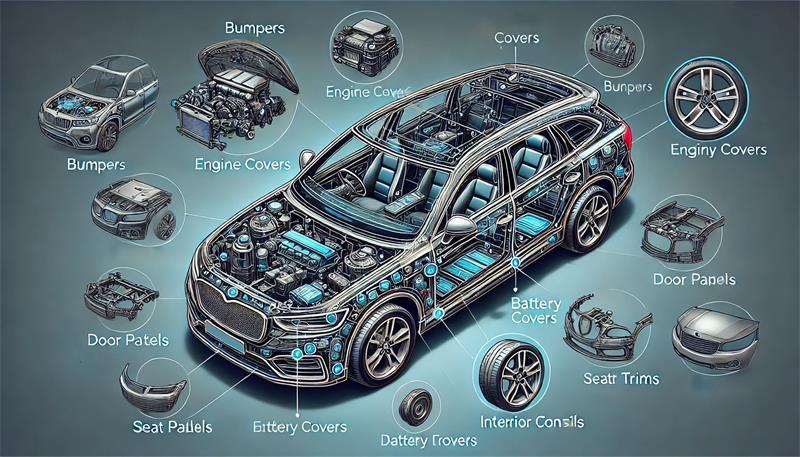

The automotive industry continuously seeks innovative manufacturing techniques to meet the demands of quality, efficiency, and cost-effectiveness. Thermoforming has emerged as a versatile and reliable technology that offers significant advantages for producing various automotive components. This article explores how thermoforming can be effectively utilized in the automotive industry, its benefits, and the professional design solutions we provide to ensure superior results.

10

2022-01

In the highly regulated and precision-driven field of medical device manufacturing, the choice of production technology can significantly impact product performance, cost, and compliance. Thermoforming has emerged as an increasingly popular method for creating durable, lightweight, and aesthetically pleasing shells for medical devices. Here’s how thermoforming can be utilized for medical device shells, the advantages it offers, and the professional design solutions we can provide to ensure optimal results.

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Ameixin Plastic Group Company was established in 2000, Now we have branch companies located in ShenZhen , HuiZhou , HongKong , Australia. We have our own factory over 18000 square meters. and passed the ISO 9001:2005 of certification.

Contact us

Contact us

Tel : 86 13240666686 / 86 15089202528

Email: Sam@szameixin.com

Ken Lai: +86 18933236697

Email: Sales04@ameixin.com.cn

Copyright © 2022 ShenZhen Ameixin Plastic Co.,Ltd